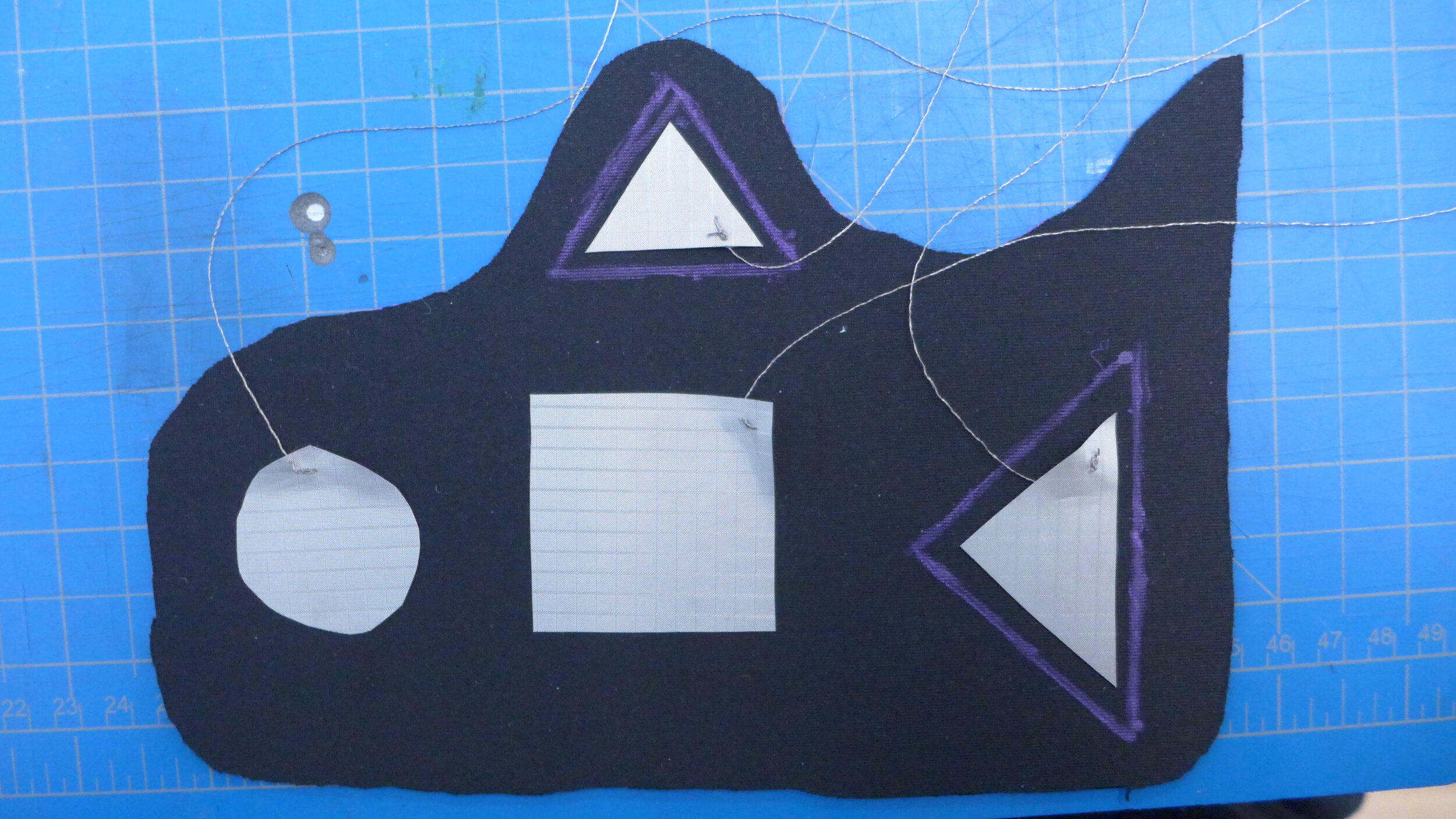

For this project, I made a textile interface that acts as a controller for Ableton Live. This project was an exploration in soft materials and rapid prototyping over the course of a weekend. You can see the full documentation of the process here.

I used the following technologies and softwares:

Arduino

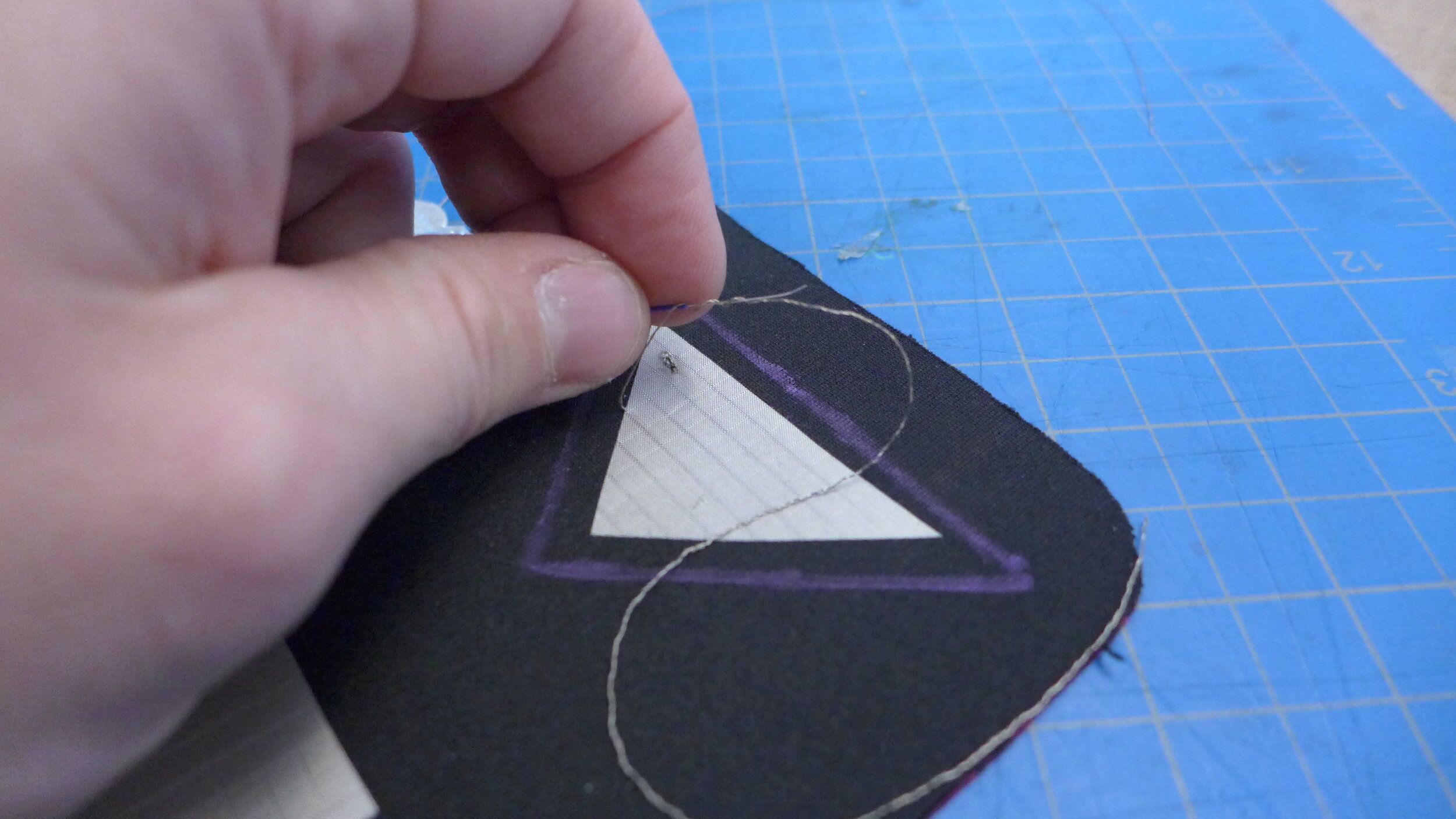

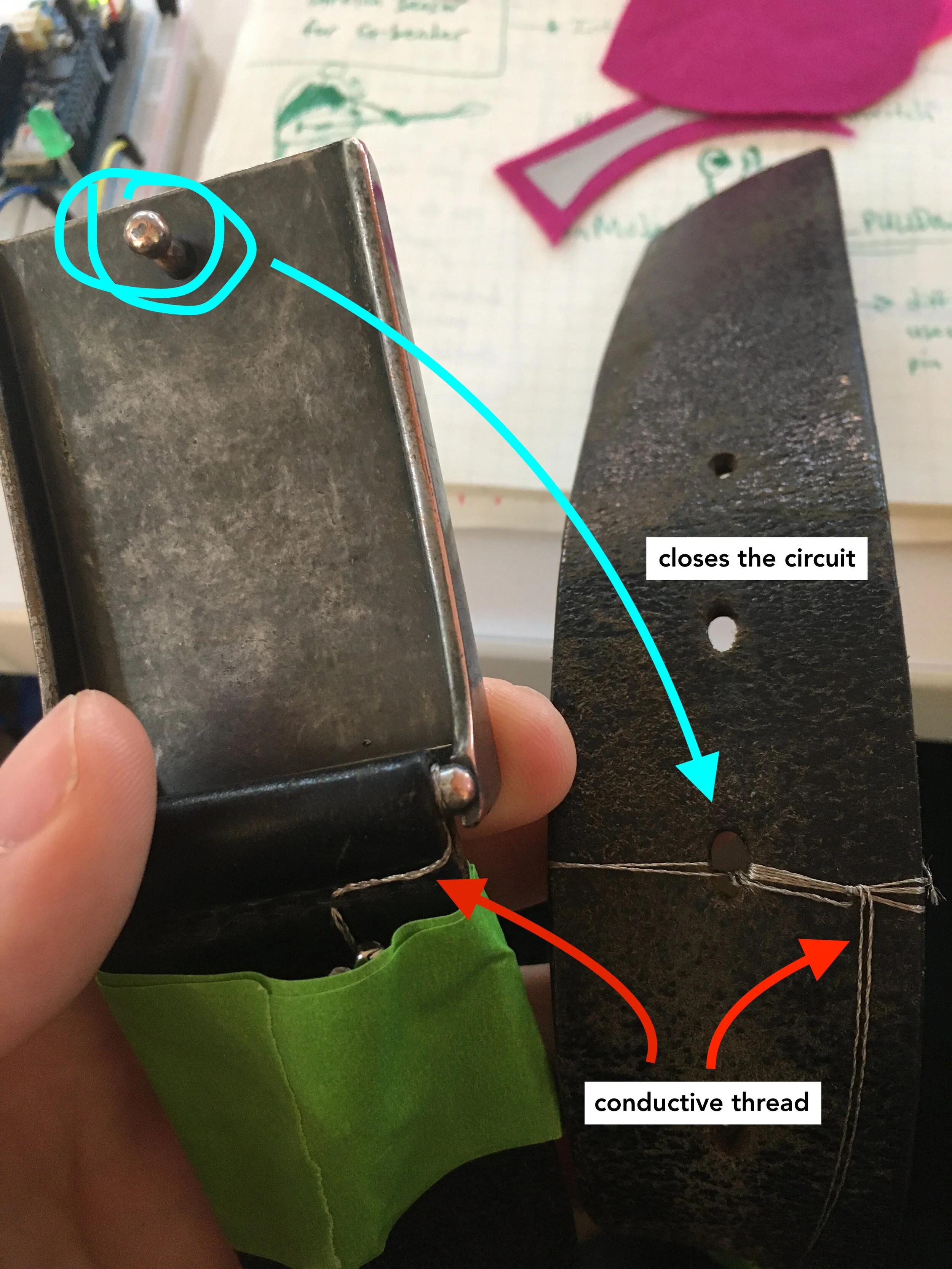

Velostat pressure-sensing material

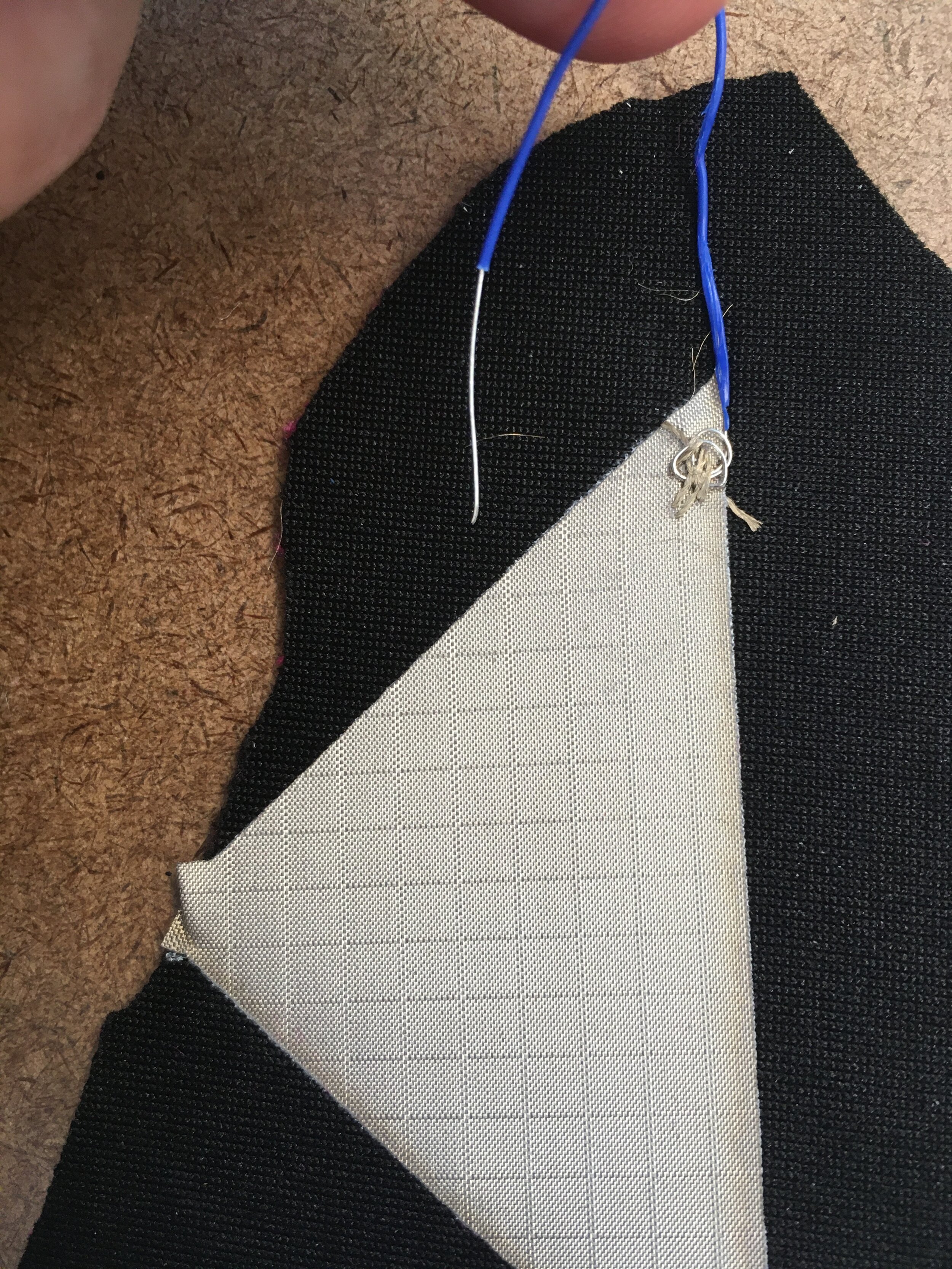

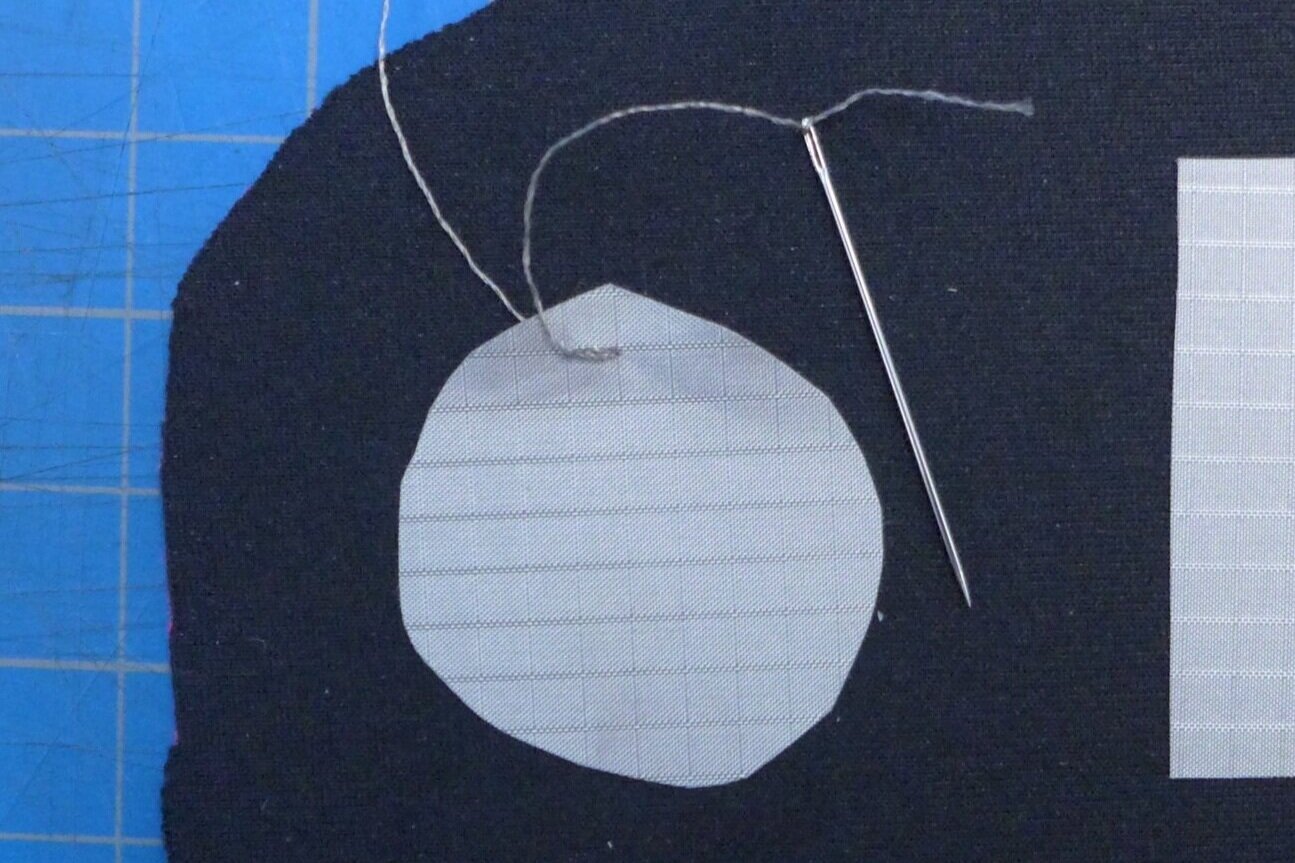

Conductive fabric

Neoprene

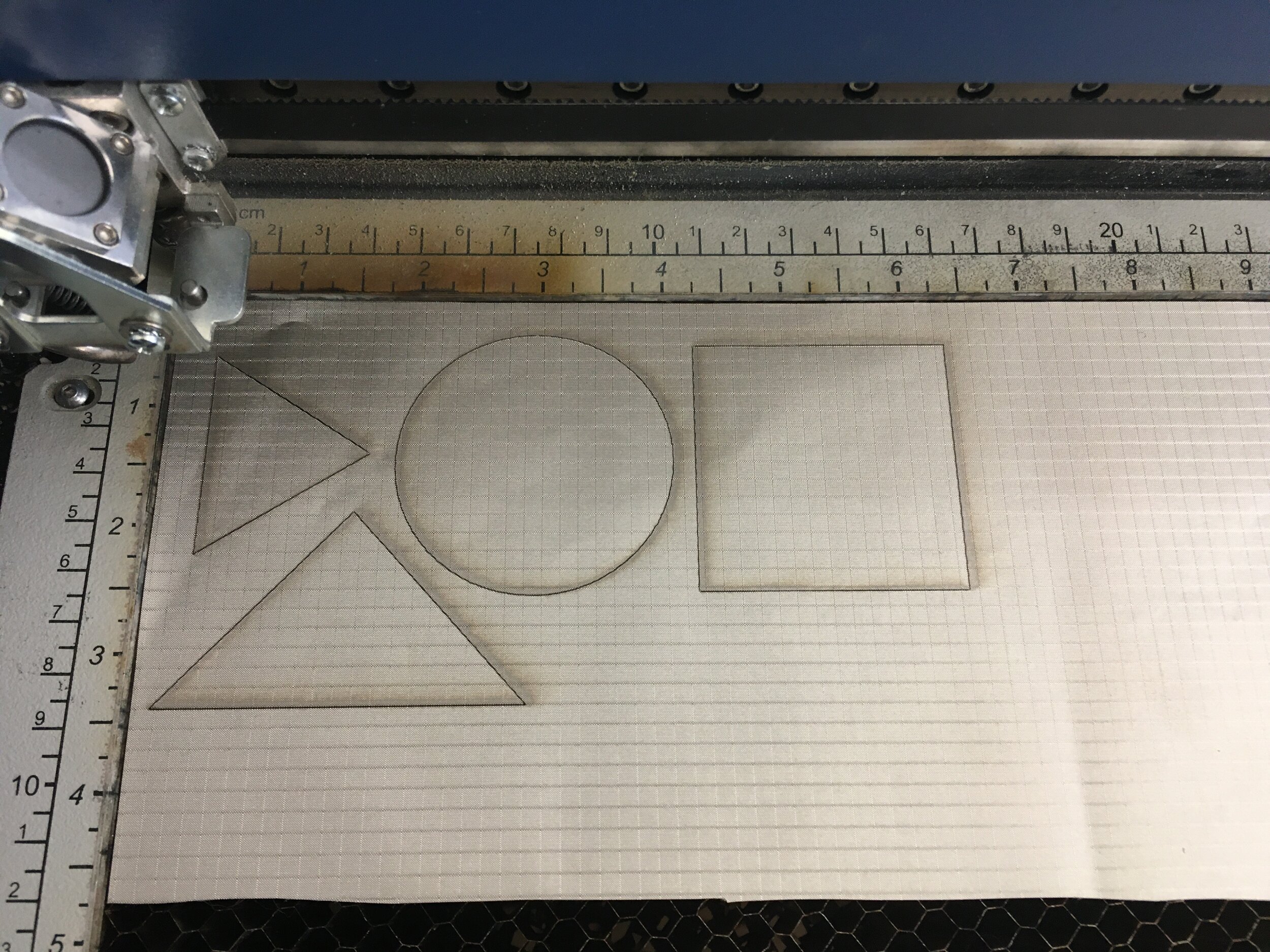

Laser cutter

Conductive thread

Vectorworks

MaxMSP

Ableton Live

C++

OSC/UDP network communication