Water Jet Cutting is an abrasive cutting technique that uses a very fine stream of water at 60,000 psi. Sometimes the water can have an abrasive cutting agent, like those used in sand blasting.

Commonly cut materials:

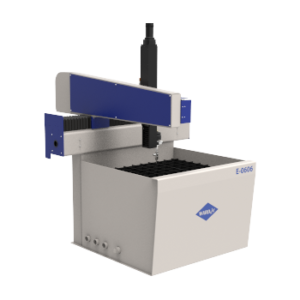

The Wardjet E-606 Waterjet Cutter at Tandon Maker Space.

metals (aluminum)

stone (marble)

glass (not tempered, because of shattering)

.DXF and .STL files are the common delivery method for these machines.

There are two spaces that I researched here in Brooklyn - NYU’s Tandon Maker Space and the FutureWorks Makerspace. I phoned both of them to find out a few tips to use when designing for waterjet cutting. They were both available by phone and the person who answered the phone was the same one who answered my questions.

The water jet bed is currogated.

The Tandon Space is FREE for students, but you must provide your own material. They have have a 24”x24” bed. They only take .DXF files. Once you mail in your file, response time is typically 24 hours. And the schedule is first-come, first-serve. It seems that the water jet does not get a lot of action.

I was thinking of cutting a tubular piece of acrylic, but they pointed out that it would be hard to mount and recommended wood-cutting tools instead. This brought up the issue of tabs, which are small pieces of your design that are used to mount the piece to the cutting bed with a number of vices. These are essential to keeping the piece in place while the cutting is taking place. With waterjets, significant movement can occur and the material can fall through the cutting bed into the water beneath as the cutting bed is currogated. The staff there will help you design these tabs, where as paid services will charge by the hour for this. Make sure to follow the submission guidelines online. You can email your file to tandon-waterjet@nyu.edu or call (646) 997-3058 for more information.

The Flow Mach 2 Waterjet cutter.

The FutureWorks space has a Flow Mach 2 Waterjet with a 4’x4’ bed and can cut materials up to 3-4” thick. They charge $100/hr however, for non-members (members pay $60/hr). As stated above, this time includes any extra design time needed to adjust your files to be cuttable. They take .STL or .DXF files. You can email prototype@makerspace.nyc to get a quote or call (718) 525-5893 for more information. They do not allow anyone but trained staff to run the water jet since it is such a expensive and dangerous machine. This is the same for their CNC Mill and ShopBot router. Attending the cut is not standard and would require special arrangements to be made.

Fun Facts

A full machine package can range in cost from $5,000 for introductory machines to $600,000 for the largest industrial models

Waterjets need industrial levels of electricity to power the pumps - as much as 50 amps with up to 250 amps to get the pumps started.

Smaller models can cut soft material like diapers, candy bars, and thin soft wood.

The WARDJet - Z-3043 Waterjet Cutter.